Thousands of sensors speckle the seas, harvesting a variety of data on the marine environment: its movement, light, temperature, sound, mass, and biogeochemistry. In the hustle to collect more information about the ocean, governments, scientists, and researchers are deploying low-power, cost-effective sensors, most of which are never retrieved.

Sensors transform from tools to trash when they settle on the seabed, wash ashore, or join a floating garbage patch. Biodegradability may offer a means to reconcile the expansion of ocean sensing with reducing sensors’ environmental footprints.

Now, scientists at the Johns Hopkins University Applied Physics Laboratory are crafting a prototype sensor composed of an innovative elastomer—a rubbery and biobenign material that is not harmful to the environment as it degrades. Plastic versions of the Velella sensor (inspired by the shape of the jelly-like creature Velella velella) have already been deployed to collect data on salinity and temperature in the Atlantic waters around the Azores.

Leslie Hamilton, a materials science engineer working on the Velella project at the Johns Hopkins University Applied Physics Laboratory, said she and her team are looking to strike a balance between forging a material robust enough to hold shape against the elements and responsive enough to degrade after it collects enough data.

If the team receives funding to continue the project, users could deploy future generations of Velella sensors in large “schools,” Hamilton said.

Adding Ocean Trash

“There’s a recognition that we’ve basically been undersampling the ocean for many decades.”

Deploying fleets of in situ sensors signals a growing trend in ocean monitoring, said Melissa Omand, an oceanographer at the University of Rhode Island who develops novel ocean sensing equipment.

The approach offers the targeted, high-resolution sensing necessary for observing climate change processes that remote sensing can’t capture. The exchange of heat between the atmosphere and the ocean surface, for instance, occurs on 10-kilometer scales, which only ocean sensors can detect. Satellites that operate between 100- and 1,000-kilometer scales fail to measure such smaller-scale dynamic processes that drive climate change. Omand said the only way to capture this vital information is by deploying large swaths of ocean sensors, gathering many data points to create an accurate, coherent picture.

“There’s a recognition that we’ve basically been undersampling the ocean for many decades,” Omand said.

It’s an unfortunate truth that discarded ocean sensors add to marine debris, Omand added, because the tools are largely considered expendable. The financial cost and ship-based carbon emissions needed to recover sensors match or outweigh the environmental damage from leaving them in the sea, she explained.

Most Argo floats sink to the seabed, adding an estimated 1.6 metric tons of plastic to the ocean annually.

Consider the roughly 3,800 operational Argo floats managed by the Global Ocean and Global Climate Observing Systems and the United Nations World Climate Research Programme. These roughly meter-tall sensors resembling yellow syringes are spread across the world, recording water temperature, salinity, and pressure. At the end of their battery-dictated life spans (a maximum of 6 years), most Argo floats sink to the seabed. Although plastic makes up less than one tenth of the mostly aluminum sensors, the dead floats still add an estimated 1.6 metric tons of plastic to the ocean annually. Such synthetic plastics are thought to take hundreds or even thousands of years to break down. But according to Argo’s environmental impact statement, “presently there is no method of observing the global subsurface ocean that is more cost effective and less environmentally damaging than Argo.”

Environmentally Conscious Materials

In 2021, Omand cofounded Nereid Biomaterials, an interdisciplinary team of experts dedicated to creating bioplastics that will degrade in marine environments. The group has developed biomaterials based on a polymer that bacteria produce naturally, called polyhydroxybutyrate (PHB), and that marine microbes have evolved to break down.

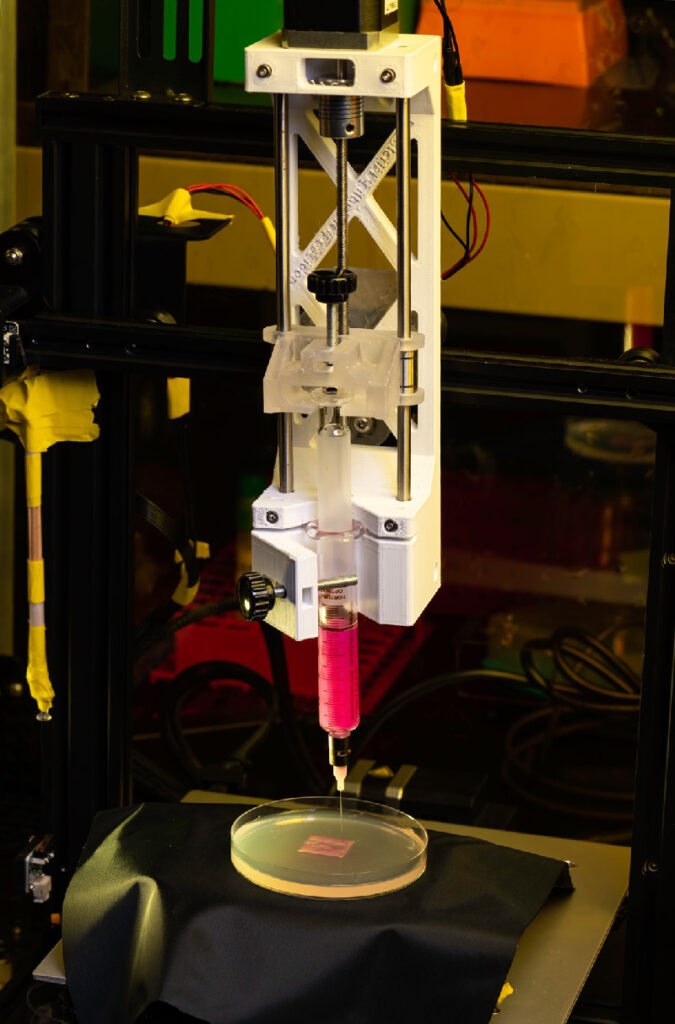

Nereid Biomaterials biologist Anne Meyer said it can take 135 years for 2 kilograms of polylactic acid, a type of plastic, to degrade in the ocean, but 2 kilograms of PHB degrades in 7.5 years—18 times faster. At her University of Rochester lab, Meyer is 3D printing living bacterial cells to explore the next frontier: controlling and accelerating the rate of biodegradability.

In coming months, more than a dozen Nereid Biomaterials’ industry partners committed to using PHB will deposit their instruments in the ocean. Then they will watch and wait. Time will reveal the bioplastics’ efficacy and whether, in coming decades, fleets of biodegradable ocean sensors will pioneer a new standard for sustainability in ocean monitoring.

—Lisa Aubry, Science Writer

This piece was produced with support from the National Association of Science Writers’ David Perlman Virtual Mentoring Program.