NASA’s Artemis mission aims to put humans back on the Moon in less than 2 years, and the China National Space Administration plans to follow suit soon after.

As astronauts return to the lunar surface for increasing periods of time, they will need structures that shield them from the Moon’s intense temperature fluctuations. In a day, temperatures can swing from 121°C (249.8°F) to −131°C (−203.8°F).

“Lunar regolith has silicon, it has oxygen elements, it has carbon. We have everything that we need to build. We just have to come up with technologies to utilize it in different ways.”

A creative solution may lie in structures made from “mooncrete,” a concrete analogue made from Moon rocks. Lunar regolith concrete (LRC) can effectively regulate temperature when exposed to dramatic fluctuations, according to new research that will be presented on 15 December at AGU’s Annual Meeting 2025 in New Orleans.

“Lunar regolith has silicon, it has oxygen elements, it has carbon. We have everything that we need to build,” said coauthor Arup Bhattacharya, a building scientist at Louisiana State University in Baton Rouge. “We just have to come up with technologies to utilize it in different ways.”

Making Mooncrete

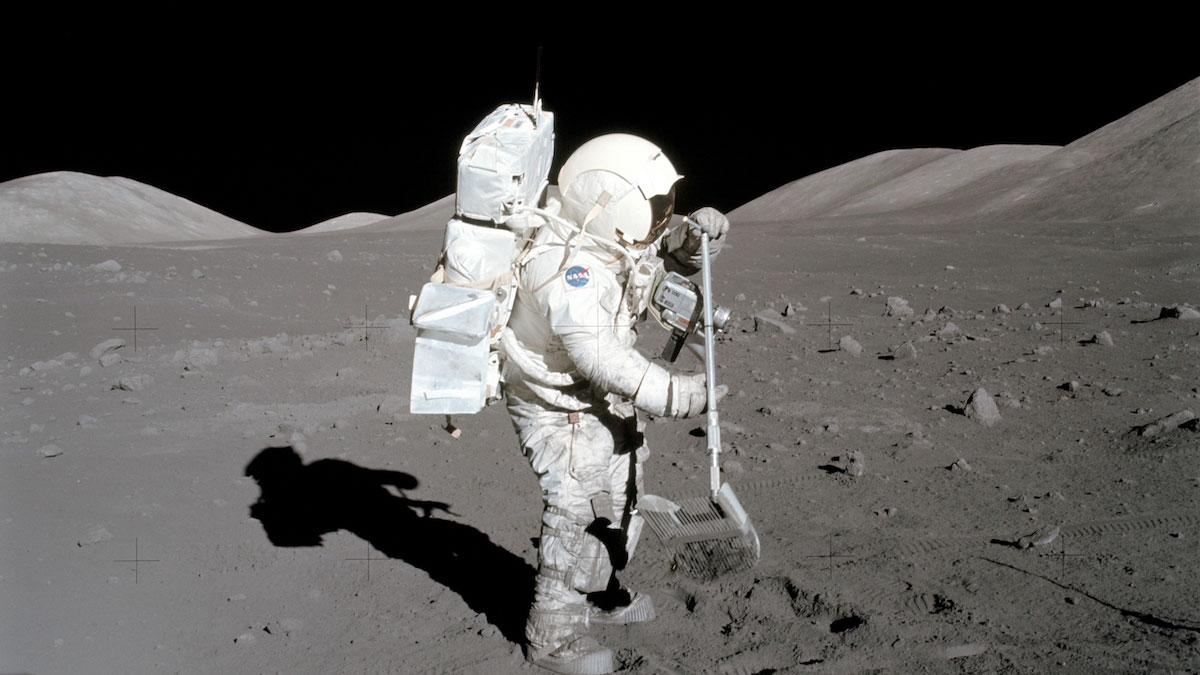

Lunar regolith is a thick layer of rocks and dust that covers the entire lunar surface. The material is packed with minerals that make it durable, including many elements used on Earth to make concrete. To turn regolith into usable building material, scientists combine it with a binding material like sulfur, which is also available on the Moon’s surface.

Because opportunities to collect Moon rocks are few and far between, all the LRC in existence was created from 40 grams of regolith acquired during the Apollo 16 mission more than 50 years ago. Most experiments today use LRC analogues made from materials available on Earth.

To investigate how mooncrete might react to extreme heat and cold, the research team used data from previous experiments on lunar regolith properties to simulate a dome-shaped structure made of LRC.

The simulated structure effectively maintained an indoor temperature of 22°C (71.6°F) when subjected to the harsh lunar temperature swings. In addition, the team found that mooncrete’s insulating effects were amplified when two layers were nested on top of one another, separated by a thin layer of empty space. Heat travels less efficiently in the vacuum of space than through solid materials, so separating layers of LRC with a layer of space makes it harder for either intense heat or intense cold to penetrate the walls.

A Cost-Effective Option

Bhattacharya is “very optimistic” that structures made of lunar regolith will be built on the Moon. Using regolith is also cheaper than other options: Though estimates vary depending on the type of material, sending just 1 kilogram (2.2 pounds) of supplies to the Moon could cost more than $100,000.

“It’s the most abundant material on the Moon, its thermal conductivity is relatively small, and it can produce concrete. I think these structures will definitely be produced.”

“We could save a lot of money if we could use materials found on the Moon to build these structures,” said Adhrit Maiti, a tenth grader at Baton Rouge Magnet High School in Louisiana and first author of the study.

The study fills an important gap in lunar habitat research, said Marcello Lappa, an aerospace scientist at the University of Strathclyde in the United Kingdom who was not involved in the study. Much of the current research focuses on how to collect and process lunar regolith, yet the safety of astronauts depends on how well LRC can handle intense temperature cycles.

“It’s the most abundant material on the Moon, its thermal conductivity is relatively small, and it can produce concrete,” Lappa said. “I think these structures will definitely be produced.”

—Kaia Glickman, Science Writer