Takao Doi’s dream is to go to the Moon and plant a tree. The former astronaut is inspired by ancient wooden shrines and temples in Kyoto, Japan, that have lasted more than a thousand years.

“If we can use wood in space, we might be able to have sustainable space development forever,” said Doi, a professor at Ryukoku University.

The idea of a wooden space age gained traction last year with the launch of LignoSat, the world’s first wooden satellite to reach orbit. LignoSat, developed by Doi, a group of Kyoto University scientists, and logging company Sumitomo Forestry, is a CubeSat—a type of minisatellite that is relatively inexpensive and easy to construct. LignoSat’s structure is meant to reduce its environmental impact because wood is a renewable material and creates less pollution when it burns up on reentry into Earth’s atmosphere.

LignoSat was deployed from the International Space Station (ISS) last year by the Japan Aerospace Exploration Agency (JAXA) and stayed in space for 116 days.

“We think wooden satellites orbiting around the Earth are the future.”

Doi and his colleagues are using what they learned to develop LignoSat-2, which they expect to launch in 2028. And they’re not alone—at least one other group is also developing a wooden satellite.

“We think wooden satellites orbiting around the Earth are the future,” Doi said.

Raphaela Günther, an aerospace engineering Ph.D. student at Technische Universität Dresden in Germany who is not involved in the LignoSat project, said she considers the work from the Kyoto University team to be a “small breakthrough” in renewable space materials research.

Lessons Learned

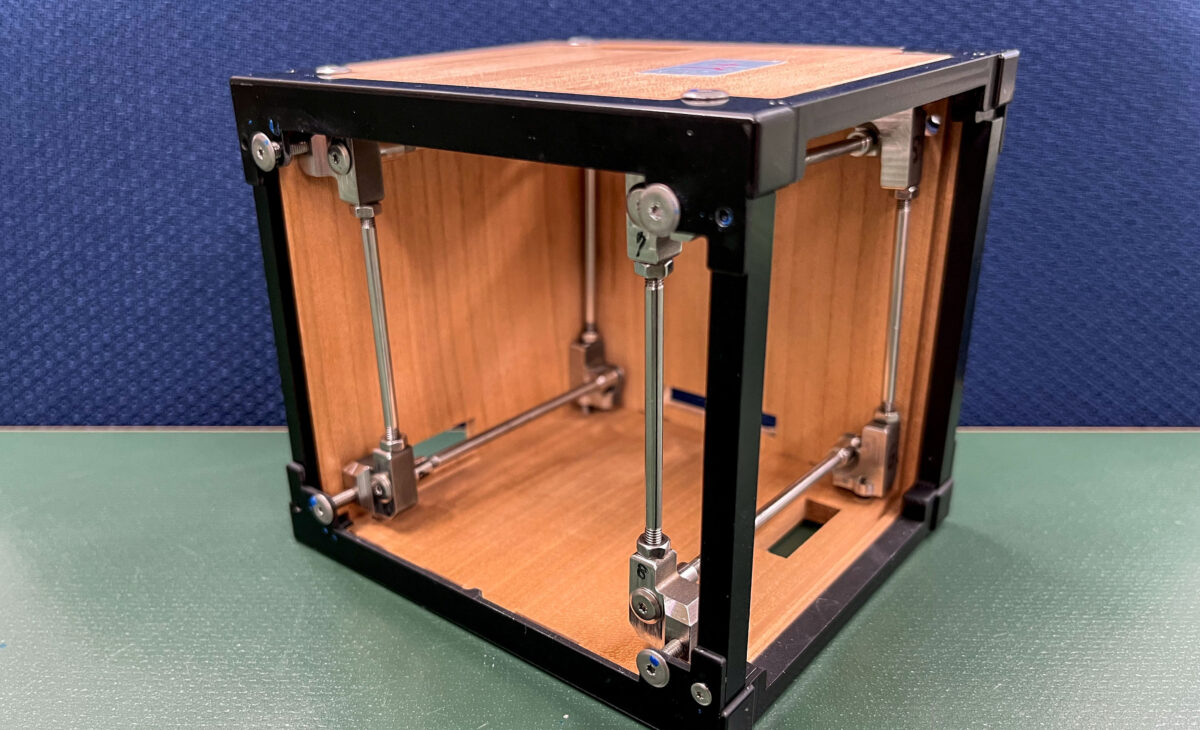

The first LignoSat was a 10-centimeter cube made of magnolia wood panels assembled with traditional wooden joinery. An aluminum frame reinforced the structure.

The LignoSat mission had five goals: to measure strain on the wooden structure, to measure temperature inside the satellite, to demonstrate how permeable wood is to magnetic fields in space, to analyze the effects of space radiation on wood, and to establish two-way communication with scientists on the ground.

After the satellite was deployed from the ISS on 9 December 2024, though, scientists in Kyoto weren’t able to communicate with it.

Orbital data from the U.S. Department of Defense show the satellite stayed in one piece during its time in space, proving wooden satellites can work, Doi said. But without the ability to communicate with the satellite, the other four missions weren’t able to be completed, either.

“Unfortunately, we didn’t receive any of the information we wanted to know about,” Doi said.

An analysis indicated that the loss of communication could have been caused by two failures: First, any or all of the three switches needed to activate the satellite system and deploy its antenna may not have turned on, and second, the computer program used in the system may not have started up as expected, Doi said. “We are still analyzing what happened, but we now have two reasons to further investigate.”

Despite the lack of communication, Doi recognized two achievements in the LignoSat mission. First, it demonstrated that a wooden satellite can exist in orbit without falling apart. Second, it streamlined the review process for wooden spacecraft. NASA must complete a safety review of all satellites that head to the ISS, he explained, and now that such a review was completed for LignoSat, reviews for subsequent wooden satellites will be simpler.

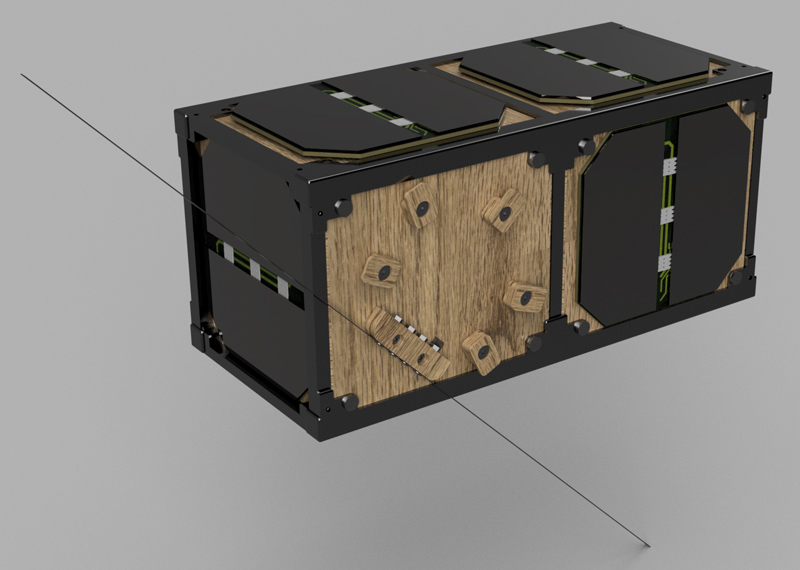

The Kyoto University team plans to build LignoSat-2 to be twice the size of LignoSat, with two communication systems (one inside the structure and another attached to its surface). Installing the antenna inside the satellite body reduces the drag of the structure as it orbits Earth, Doi said.

“Even if the antenna is not deployed, which might have been the cause of LignoSat 1’s communication problems, we may be able to use this second communication system to communicate with [LignoSat-2],” Doi said.

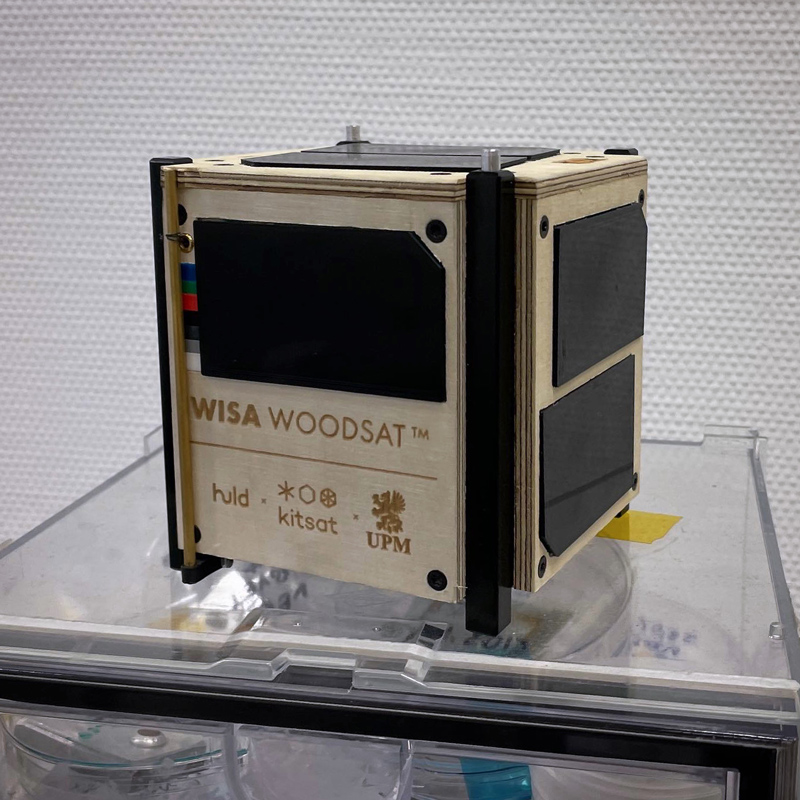

Finnish space technology company Arctic Astronautics is also thinking about wood in space. In 2021, they and Finnish company UPM Plywood developed the WISA Woodsat, a 10-centimeter birch plywood CubeSat. The satellite contains a suite of sensors meant to gather information about how outer space affects wooden spacecraft. It has a deployable camera, a “selfie stick” meant to take photos of itself in space and allow the team on the ground to monitor it visually.

“There is a niche for these kinds of satellites, and the basic research is extremely interesting,” said Jari Mäkinen, cofounder of Arctic Astronautics and initiator of the WISA Woodsat project. “It’s totally possible that when we see these satellites flying, we realize important information [about how plywood acts in space].”

The WISA Woodsat itself is nearly ready for launch, Mäkinen said, but Arctic Astronautics still needs permitting from Finnish space authorities to proceed. He’s hopeful the launch will take place next year. “We will fly as soon as possible,” he said.

A Sustainable Space Industry

For Doi, the wooden CubeSats are just the beginning. “Let’s create a space timber industry” reads the translation of the bio of the research team’s X (formerly Twitter) account. Doi said he imagines a future where wood overtakes aluminum as the primary material for satellites.

Wood is cheaper, easier to use, and lighter than conventional spacecraft materials. Its use as a potential material could both push the space industry toward using more wood and make space development more accessible to countries with fewer resources, Günther said.

A wooden space age could shrink the environmental footprint of the space industry, too. When aluminum satellites fall back into Earth’s atmosphere, they burn, creating aluminum oxide particles. These particles, sometimes smaller than 1 micrometer, may destroy ozone, disrupt atmospheric processes, and even alter Earth’s magnetic field, some scientists suggest. When wood burns, it generates only carbon dioxide, biodegradable ash, and water vapor.

And though scientists don’t fully understand all the possible ways that particles from decomposing metal or wooden spacecraft interact with the upper atmosphere, the decomposition products of wood are easier to assess because they are already major drivers of atmospheric processes, Günther said.

“It’s not a question if we do or if we don’t” begin to use more sustainable spacecraft materials, she said. “I think we have to.”

With a few hundred tracked objects returning to Earth each year, reentering metal spacecraft are not currently a major environmental problem. But as the space industry quickly grows, it’s crucial to look for more ecofriendly materials, Doi said. Replacing even a small portion of parts on future satellites with wood could significantly reduce pollution, Mäkinen said.

Wood poses challenges for spacecraft engineers, too. Because it’s grown naturally, it has defects and doesn’t behave homogeneously, meaning “the behavior of the material in three different directions is not the same,” Günther said. Her own research is working to create spacecraft materials made of wood fibers and binding material that behave more consistently.

“It’s not a question if we do or if we don’t” begin to use more sustainable spacecraft materials, she said. “I think we have to.”

Mäkinen agreed that wood provides many environmental and technical advantages but said large space companies have likely invested enough in their current manufacturing processes that a large-scale shift to wood as a satellite material is unlikely without pressure from space authorities. “I hope that I’m wrong,” he said.

—Grace van Deelen (@gvd.bsky.social), Staff Writer